In today’s market, and especially in the world of produce, traceability has become more than just a requirement, but an absolute necessity for those involved in this industry. Besides being a powerful tool for the areas related to food safety, strong traceability allows growers and their distributors to have full control over the supply chain process. In the case of any potential product withdraw from the market or a full-scale recall, producers, shippers, and retailers have the responsibility to act quickly and be fully capable of tracing the product to its origins. In addition, having an adequate trace system can help with other issues related to product quality and product defects occurring in the market place. At Divine Flavor, we have developed a simple, but yet efficient way to trace product at all of our ranches. Let’s take a deeper look of how the process starts once product leaves the farm.

Last year, in September, we visited with Divine Flavor growers Agricola Cueto & AC1 Cueto. Here is a recap of the systems they have in place for traceability at the farm level: Click here to see more about our traceability program.

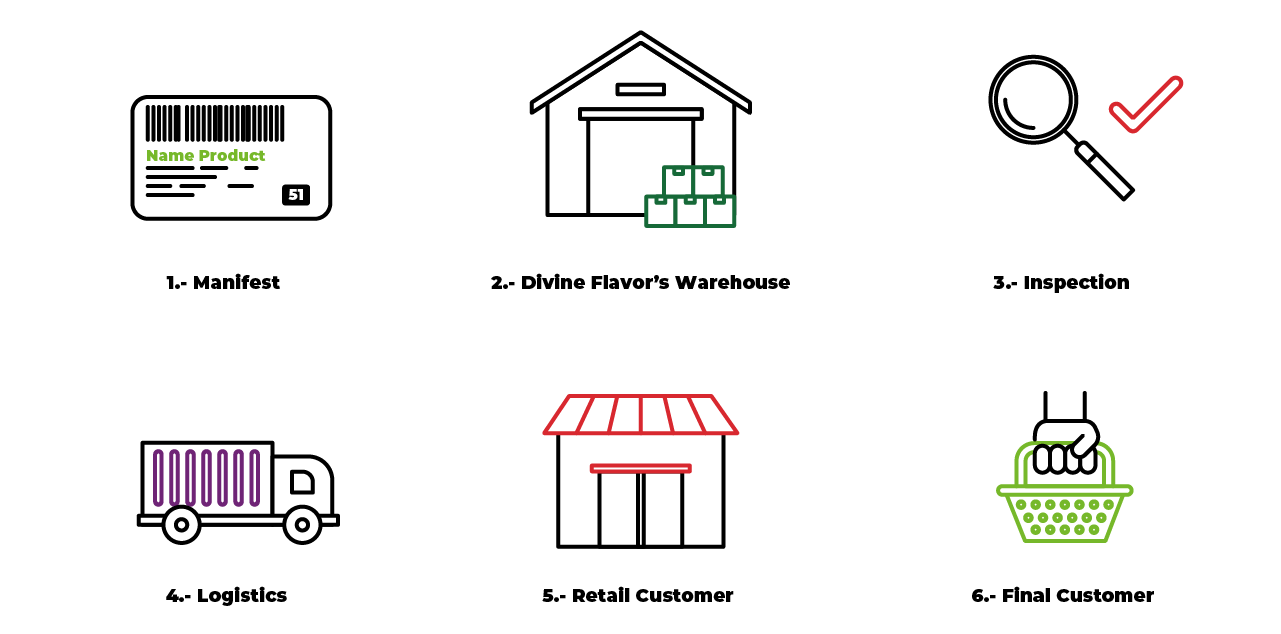

Traceability at the farm-level is just one part of the supply chain. In fact, depending on the amount of facilities in contact with the product on its way to the final consumer, all of those divisions may be involved with the process. For example, if produce is delivered from a grower to a distributor, and a distributor to a broker, each of those parties need to have a good system in place to understand where product is being sold as the final destination. For Divine Flavor, the process is quite simple. Product is sent from the farms where it arrives to our cold storage distribution facilities here in the USA. From here, the produce is held in proper temperature controlled environments until our customers (retailers and wholesalers) have purchased the product and have arranged to pick it up. From our distribution center (DC), the customers deliver product to their DC which then take the product to the grocery stores where consumers can purchase the product. In short, our farms deliver to Divine Flavor’s DC, our DC to the client’s DC, from their DC to their markets. Simple, right? Only if the proper systems are in place, which I’ll highlight below.

As shown in the September issue, the farm must have a strong internal system in place. Their last step of the process (the manifest) is actually Divine Flavor’s DC’s first step to the process. Once the manifest for the produce being sent to Divine Flavor is generated, copies are sent to our DC, as well as physical copies with the truck. When product arrives at our DC, the manifest information is entered into our system which includes various amounts of detail- pallet tag numbers, weights/sizes, etc… From here, this allows our sales team to sell product to the different customers.

Many purchase orders can be made from a single manifest, but linking those POs to the manifest is a crucial component to the traceability process. In most cases, multiple POs can come from a single manifest. An important element that allows us to track product are the pallets of product have specific numbers associated to them which is all linked to the manifest the product came from. Each PO contains specific information which allows us to know where the product is going and when it is set to arrive.

OUR TRACEABILITY PROCESS

PTIs on the packaging

Physical inspection & manifest deviation control

Another important factor is having proper labeling on the retailer units that are ordered by the retailers and wholesalers. This labeling is referred to as the Product Traceability Initiative (PTI). The PTI is a mandatory label that must accompany each box of produce delivered to Divine Flavor. The idea behind the PTI is to contain information such as barcodes, country of origin, product descriptions, and information related to traceability (pack dates, grower identification, etc.). On the PTI, it is important to have human readable information that allows our Quality Assurance and Quality Control teams to know, very quickly, important information related to where the product came from.

Quality inspections

All product arriving to Divine Flavor’s distribution center must undergo a physical inspection. This allows our Quality Control teams to verify the amount of product reported on the manifest to what physically arrives. At this time, our quality control professionals inspect product to make sure it arrived in good condition and that it meets the expectations of our customers and our consumers. Having good traceability helps prevent future quality problems from occurring in the market place. As many of us in the produce industry know, fruits and vegetables can have a mind of its own. What looks to be a healthy crop during the harvest and packing can sometimes hide its smallest details that aren’t discovered until our quality teams inspect the product here at our distribution facility.

Since harvesting details are such an important factor and recorded properly during the early stages of the trace process, our QC teams can easily communicate to our farm teams about trending/reoccurring issues we see here at the DC. Certain sectors of the ranch can be isolated and inspected by the quality engineers to correct problems causing quality defects with the product. At each phase of the supply-chain (farm, DC, and customer’s DC) quality reports are generated to make sure the product being sold to consumers is consistent and is of the best quality.

Product assortment & product organization

The last step of the traceability process is from our client’s DC to the store which it is sold. Over the last decade, technology has played a significant role for allowing produce companies to keep track of where product is being sent. When a customer makes a purchase of Divine Flavor’s product, this in a way is very similar to how manifest are sent to us from our ranches. A document trail showing which order number the product came from is in place for each shipment sent to the grocery stores and markets our product is given to. Once store receives product from their DC, that information is linked to the PO it came from. The PO corresponds to the manifest, which then corresponds to which ranch the product was grown. From here, we know which day it was grown and from which greenhouse it came from. Having a process which allows you to see each part of the supply-chain and how information accurately links together is how traceability succeeds. Manifest deliver to – Photo

Product is ready to be shipped to our customer

To be able to trace product from our customer’s favorite grocery stores all the way back to Divine Flavor’s ranches gives shoppers the confidence that we are growing Better Food for a Better World.

For more information, please contact:

Michael DuPuis

Public Relations Coordinator

+1 (520)-281-8328

mdupuis@divineflavor.com